At Tekwell Services, we see a lot of different types of cranes. We do a lot of overhead crane inspections and repairs, so we are in a perfect position to give you an overview of them. There are many types of overhead cranes and these have been customized in many different ways, so this blog series is going to define the major types of overhead cranes we encounter during our inspections and repairs.

First of all, overhead cranes are also known as bridge cranes and although they are most commonly used in industrial manufacturing such as automobile manufacturing, metal manufacturing and refining, shipbuilding and aviation, they also can be seen in large warehouses moving heavy objects around for storage, heavy equipment repair, and for loading and unloading raw materials such as shipping containers, giant rolls of paper at paper mills, and energy production sites.

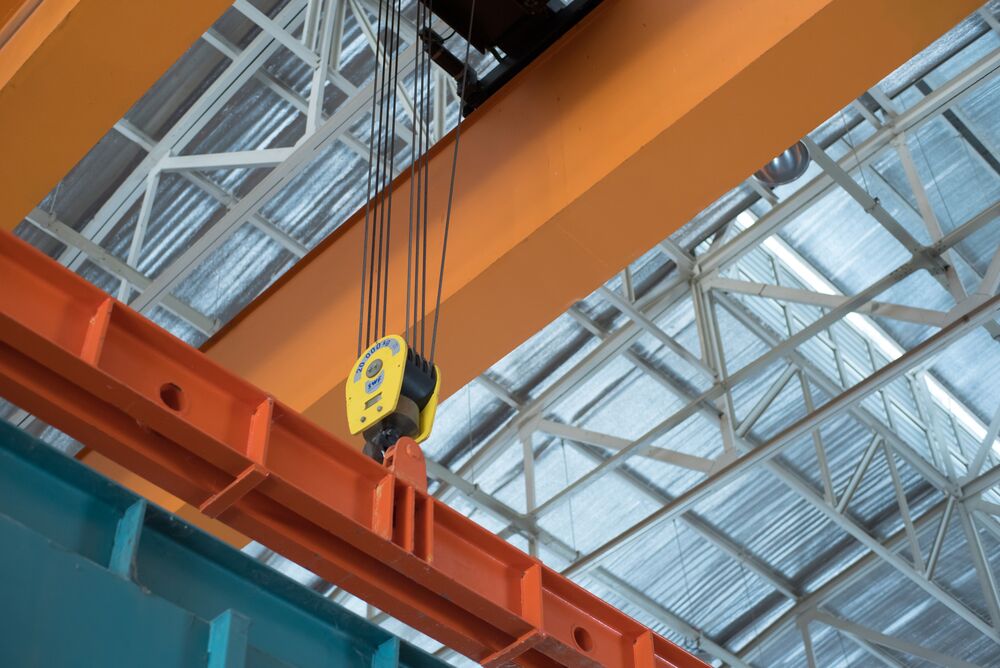

The basic components of an overhead crane are the following:

In top-running cranes, the bridge moves on top of the runways. This creates an independent means to support the weight allowing it to lift heavier loads than that of an under running crane. It also has a higher “hook height” which allows the crane to lift loads higher.

An under running crane uses the building’s existing support structure and attaches the crane underneath the bridge. This type of crane is ideal if you do not have a lot for floor space in your work area, and you don’t need to lift objects very high.

A single girder crane is probably the most common type of overhead crane we see. It is widely used in small fabrication shops, repair shops, warehouses, light manufacturing plants, and many other places that need to be able to lift and move objects up to 20 tons.

Double Girder cranes are top running cranes that use two girders as bridges for the crane. This allows the crane to lift far heavier loads than a single girder crane can handle. Double girder cranes are commonly seen in steel mills, paper mills, large fabrication plants. The double girder can handle up to 400 tons of weight and lift them higher than you could with a single girder crane.

We are specialists in overhead crane inspection and repair. It doesn’t matter if it’s a top running or underhung, single or double girder. We can inspect them and repair them. Contact an overhead crane inspection and repair specialist today by completing our online form on our Contact page or give us a call at 1-800-829-7454.