Tekwell has the expertise and tools required to repair, test, and install machinery, guaranteeing optimal efficiency and dependability, serving a wide range of electric motors from fractional horsepower to medium voltage. Here are many of the common questions we are routinely asked.

The easiest way to work with us is to fill out our simple online contact form at the bottom of any page on our website, complete our detailed Pump and Electric Motor Repair Form or giving us a call at 800-829-7454 to speak to a Tekwell Services representative right away.

Simply call our toll-free number 800-829-7454 and ask for our office manager, who will gather the information needed to set you up. Ask for an account application to set up an account when you call.

We will respond to your email or telephone request for electric motor repair, crane service or field test within 30 minutes. The actual service response varies, depending on the availability of our technicians. We will usually be able to be on site within a couple of days for routine call outs. Emergency call outs can usually be scheduled the same day.

When you call, we will call you back in less than 30 minutes, and schedule a service technician with the right experience to troubleshoot and resolve your problem to your location as soon as possible.

An SKF Certified Rebuilder is a company that has sent its technicians to complete extensive training in electrical motor diagnosis and repairs. This includes hands-on training in electric motor analysis, bearing installation, root cause analysis, condition monitoring technologies and lubrication systems using the latest technology and best practices for electrical motor repair.

To learn more about SKF Certification, check out our article: What is SKF Certification? Why is it Important? out on our blog.

EASA stands for the Electrical Apparatus Service Association, the premier international trade organization of over 1,800 electromechanical sales and service firms in nearly 80 countries. EASA provides members with steady stream of information and educational programs to help keep its members up to date on the latest materials, equipment, and state-of-the-art technology used in electrical and mechanical equipment and systems.

As a member of EASA, Tekwell Systems receives superior training and know-how which we use to better serve our electric motor and industrial pump repair customers.

We here at Tekwell Services pride ourselves on the quality of our work. We don’t take shortcuts, and take the time to do it right–the first time. We understand you don’t have time to lose. We test and retest it until you are satisfied.

We provide a premium level of service because our Field Service Technicians are highly qualified and trained, and have extensive knowledge of VFDs, PLCs, vibration testing, thermography, and alignment. When you combine this with Tekwell’s state-of-the-art repair facilities and best practices, we provide a lot more value than our cheaper competitors.

Tekwell provides service and repairs for electric motors and industrial pumps that are installed across a wide range of industries including: Chemical, Oil & Gas Production, Textiles, Industrial Plants & Facilities, Utilities, Water/Wastewater, Mining, Paper, Steel, Food & Beverage, Aviation, Military, and many more.

As an SKF Certified Motor Rebuilder, Tekwell’s Service Technicians are capable of servicing almost any brand of industrial electric motor, including: WEG, GE, Baldor/ABB, Siemens, Lafert, SEW, Marathon, and Leeson (just to name a few).

There are a lot of different types of industrial pumps out in the world these days, including: Circulating, Centrifugal, Close Coupled, Submersible, Axial Flow, Vertical Turbine, and Multi-Stage (just to name a few) and we service all of these and more.

At Tekwell we have a broad knowledge of industrial pumps, and service almost every brand out there including: Flygt, Aurora, Berkley, and Grundfos.

Not sure what you need? Just give us a call at 800-829-7454, or complete our detailed Pump and Electric Motor Repair Form to get the process started.

We can repair and test most types of AC and DC motors rated for supply voltages up to 4,160Vac or 750Vdc. Our large lifting capacity allows us to handle motors that weigh up to 20 tons. Larger motors can be repaired on site. We can fully load test motors up to 800HP/3,600RPM.

We provide a wide range of electric motor and industrial pump repair services at our two electric motor repair shops serving the Southeastern United States: One in Knoxville, Tennessee and another in Cartersville, Georgia (just outside of Atlanta).

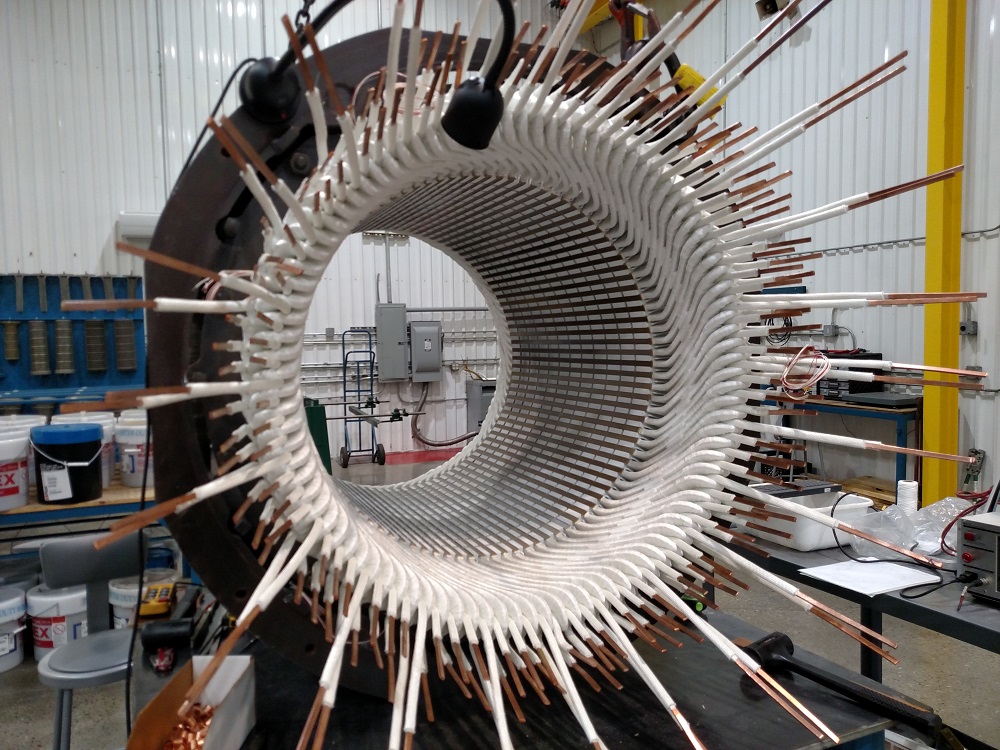

Some of the repair services we provide are: electric motor rebuilds, installing OEM replacement parts, bearing replacement, electric motor rewinding services, dynamometer load testing, VFD repair, gearbox repair, as well as a wide range of industrial pump repairs.

It depends on several factors. How old is the motor? In what conditions has it been running in? Has it been maintained properly? Either way, a good electrical motor repair will improve the efficiency of the motor’s operation from the current condition, and in some cases may bring its efficiency up to what it was when you first purchased it.

If it is more than 10 years old, it might be more economical to purchase a new NEMA motor. The energy cost savings alone will help the motor pay for itself. But there are a lot of other factors to consider such as operating costs, if the motor is in constant operation 24/7, if the motor is mission critical, and more.

Check out our blog post Repair or Replace? – 6 Things to Think About When Servicing an Electric Motor for more details and other factors to consider.

Service Factor tells us how much overload a motor can be expected to handle.

Example: A motor with a Service Factor of 1.15 can handle INFREQUENT loads that are 15% past its rated horsepower. A 10 HP motor could safely handle 11.5 HP for a short period of time without overheating.

We provide a wide range of field services for electric motors such as installations, repairs, upgrades, and troubleshooting, as well as performing predictive and preventative maintenance testing such as infrared thermographic studies and electric motor vibration analysis.

Absolutely. Just give us a call at 800-829-7454, or fill out our simple online contact form at the bottom of any page on our website, or complete our detailed Pump and Electric Motor Repair Form to get the process started.

Tekwell Services provides comprehensive overhead crane repair and inspection for many different types of overhead cranes including: Top Running, Under (Hung) Running, Single & Double Girder, Overhead Traveling Bridge, Jib, Monorail and Gantry cranes.

Ultrasonic motor testing–AKA motor vibration analysis–is an excellent, non-destructive testing method that can help uncover problems such as: faults in rotating equipment, misalignments, unbalanced loads, rolling element bearing faults, and resonance conditions.

We also perform motor and gearbox alignment, laser alignment, overhead crane inspection and repair, and many other services.

According to a recent study conducted by the Electrical Apparatus Service Association (EASA), the answer is “Yes.” If you follow good practice repair methods, then it is possible to rewind an electric motor multiple times without degrading the efficiency of it.

Electric motor repair shops can be dirty places. Working on electric motors can create dust, smoke and grime that can cause further problems for motors undergoing a rewinding service. This is why your electric motor rewinding shop must have a dedicated “clean area” for the rewinds.

Getting the dirt, paint, oil, grease and other contaminants off the windings can happen elsewhere in the shop, but once it is time for the rewind itself, the area around the motor should be contaminant free to get the best results.

Condensation caused by changing temperatures can also cause problems during the rewinding process, so your motor rewind shop should have a climate-controlled clean area dedicated to the rewinding process and any delicate electric motor repairs.

Variable Frequency Drives are commonly referred to as VFDs, Variable Speed Drives, Inverters, AC Drives, and Adjustable Speed Drives (just to name a few).

A Reduced Voltage Soft Starter is used to gradually introduce power and torque to reduce wear and tear on mechanical parts of large electric motors. They do this by eliminating damaging power spikes and reducing electrical problems associated with these spikes such as overheating, flickering lights, or even brownouts. Variable Frequency Drives can also do this, and much more.

For more information about these differences, check out our blog post: 5 Differences Between Reduced Voltage Soft Starters and Variable Frequency Drives

A Variable Frequency Drive protects your investment in large electrical motors by protecting the mechanical parts from damage and wear and tear caused by power spikes.

But a VFD can do more than that. A VFD is designed to control an electric motor using only the amount of energy that is needed for the operation. Because a motor connected to a VFD is not running at a constant rate–it saves a significant amount of energy, which reduces your energy consumption and saves a lot of money.

Variable Frequency Drives (VFDs) are designed to reduce wear and tear on the mechanical parts of large electric motors by eliminating power spikes and reducing the electrical problems associated with them.

Any situation where an electric motor’s energy requirements shift often, need to start, run and stop the motor, or require a lot of torque to start, is ideal for a VFD.

Many VFDs are just one element of a larger energy management process for complex, coordinated systems such as those running a series of conveyor belts, fans and pumps together.

Using VFDs can improve the power factor of AC induction motors, but because of the nature of what these motors are powering – fans, pumps, compressors and conveyors, these have relatively low power factors to begin with, but every little bit helps when trying to reduce overall energy costs, and–most importantly–saving wear and tear on your industrial electric motors.

We have a comprehensive inventory of NEMA Premium Efficient motors from 1HP to 400HP.