Ultrasonic cleaners have been around since the 1950s, and smaller versions have appeared in home appliances since 1970, but how does an industrial ultrasonic cleaner work?

All types of ultrasonic cleaners use cavitation bubbles—bubbles created by rapid changes of pressure in a liquid–to clean parts with lots of crevices and complex shapes within them.

Ultrasonic cleaners are popular for a couple of reasons:

The ultrasonic cleaner uses high-frequency sound waves (up to 40,000 pulses per second) to create millions of microscopic cavitation bubbles, bombard contaminants such as grease, dirt, and rust, old paint, grease, and much more attached to the part and strip them away.

An ultrasonic generating transducer generates the ultrasonic waves that produce the cavitation bubbles, either built into the ultrasonic cleaning unit’s chamber or as a stand-alone unit that can be lowered into the cleaning solution.

Because the ultrasonic cleaner requires cavitation to clean the parts, water is not an option. It has too high surface tension to produce cavitation well. As a result, special additives are added to the cleaning solution to reduce the liquid’s surface tension, and any number of detergents, wetting agents, and other chemicals as needed by the type of part being cleaned. Typically, the cleaning solution is between 122- and 149-degrees Fahrenheit to clean the parts effectively.

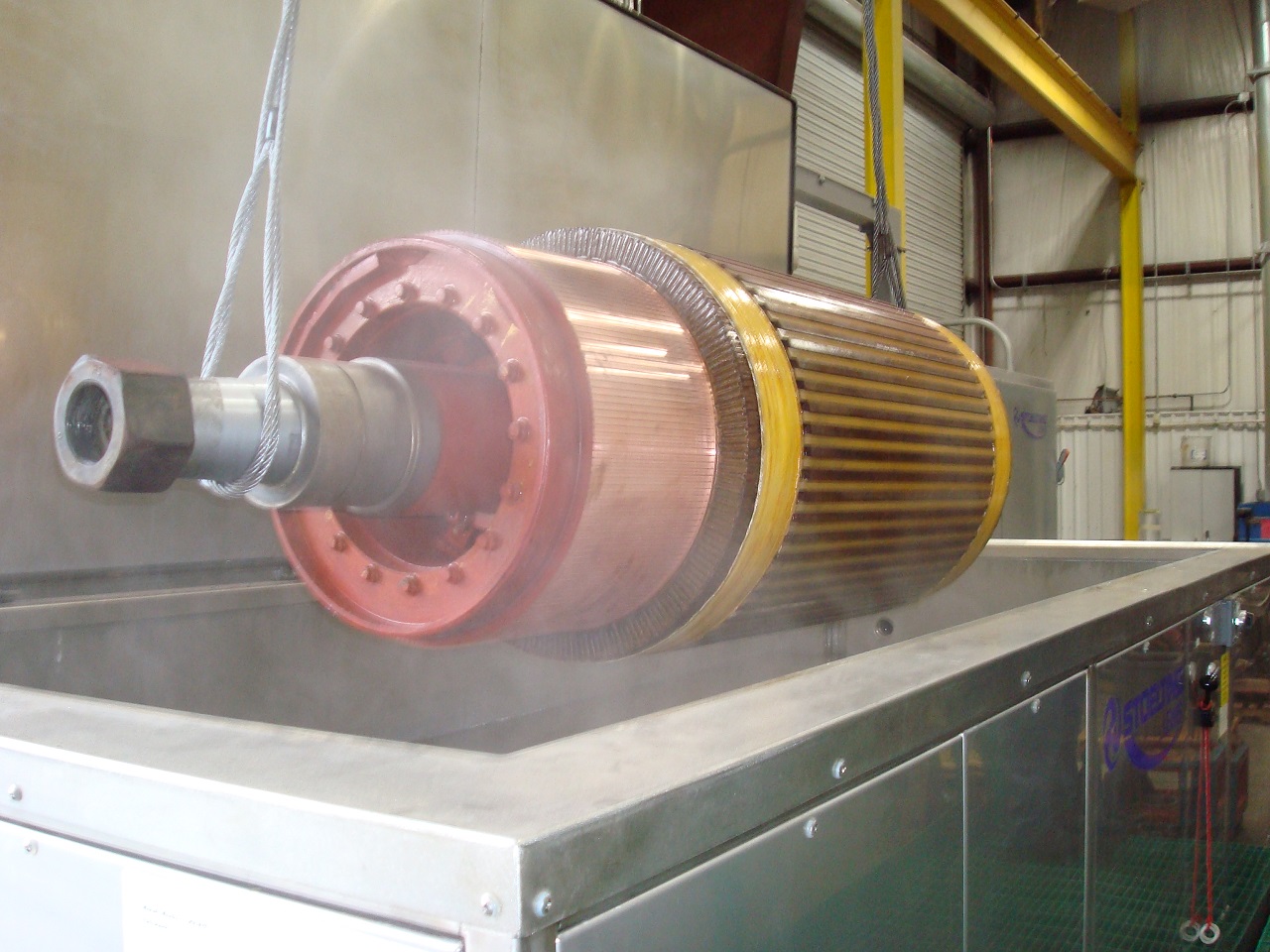

Once you have the ultrasonic cleaner set up, the cleaning solution is poured into the tank, and the process is quite simple, immerse the parts in the solution. Depending on the cleaning unit’s size, you may be able to clean many parts at one time, which again saves a lot of time and energy. The operation is simple; once the parts are in the solution, you start the system, let it run for 20 to 30 minutes, and do the job.

Our ultrasonic cleaner at Tekwell Services is large and able to clean parts up to 10 feet long, 4 feet wide, and 3 feet deep. This size also allows us to clean multiple smaller parts at the same time. For more information about our ultrasonic cleaning services, give us a call at 1-888-984-4668 or fill out our quick solution form today.