Your electric motor has broken down and you have taken it to a motor rewinding shop. What happens to it? How does the motor rewinding service process work?

The first step is that an electric motor repair technician gathers information about the motor. This includes an initial inspection. The technician looks for blocked air ducts and missing or damaged external parts. The technician should also pull information from the nameplate(s) on the motor to make sure that all of the critical manufacturer information (original manufacturer, part number, service dates, etc.) is available for the service. If data about this motor is stored in a service data management system, then it is accessed to gather the complete service history about the electric motor.

Next, the technician interviews the customer bringing the motor in for a rewind to get specific details about it. For example:

Sometimes an electric motor service technician will be able to tell from this inspection and gathered information if the motor is repairable or not, but most of the time the motor will need to be disassembled for an in-depth inspection.

An in-depth inspection requires that the technician disassemble the motor. This is a delicate process because you don’t want to damage any of the parts or other components of the motor. The tech will carefully label and store the parts for re-assembly and possibly take photos of the disassembly process.

Once the motor has been disassembled the technician looks for issues such as:

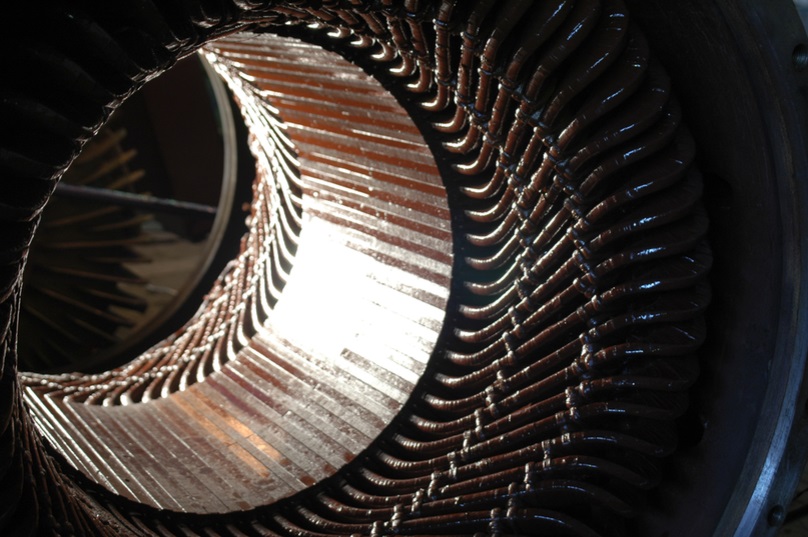

The technician then removes the winding and documents any details about the winding in the service system or on data sheets. Next, the technician typically performs core-loss testing and removes the old winding.

Next the stator core is cleaned–preferably by using an ultrasonic cleaner–to prepare it for rewinding. During this stage the technician may identify parts that need to be replaced and order them.

This is the end of part 1 of our 2-part series on the Stages of a Motor Rewinding Service. Come back again next month for the final post.

We provide motor rewinding service for most electric motor brands. Contact us for details by completing our online form on our Contact page or call us at 1-800-829-7454.